In the first part of our article, we explored the European Union’s Packaging and Packaging Waste Regulation (PPWR) and its ambitious goals to reduce packaging waste, promote sustainable packaging solutions, and transition to a circular economy. We also discussed the alarming increase in CO2 emissions and ocean pollution caused by excessive packaging waste and the need for more sustainable practices.

In Part 2 we will cover key topics like

- Extended Producer Responsibility (EPR)

- Detailed requirements and targets of the PPWR, including recyclability, reuse, and labeling requirements,

- Implications and tips for packaging producers and

- How Videojet can help

Extended Producer Responsibility (EPR) and compliance monitoring

To ensure each Member State is meeting the recycling targets of PPWR, each Member State must establish a national register to monitor compliance. These systems will improve upon the existing EPR systems that may already exist in some Member States. This would place financial responsibility on producers to manage the costs of managing the packaging—including waste management costs and cost of labelling waste bins for collection. Further information on cost implications that vary from existing EPR schemes is still to be determined.

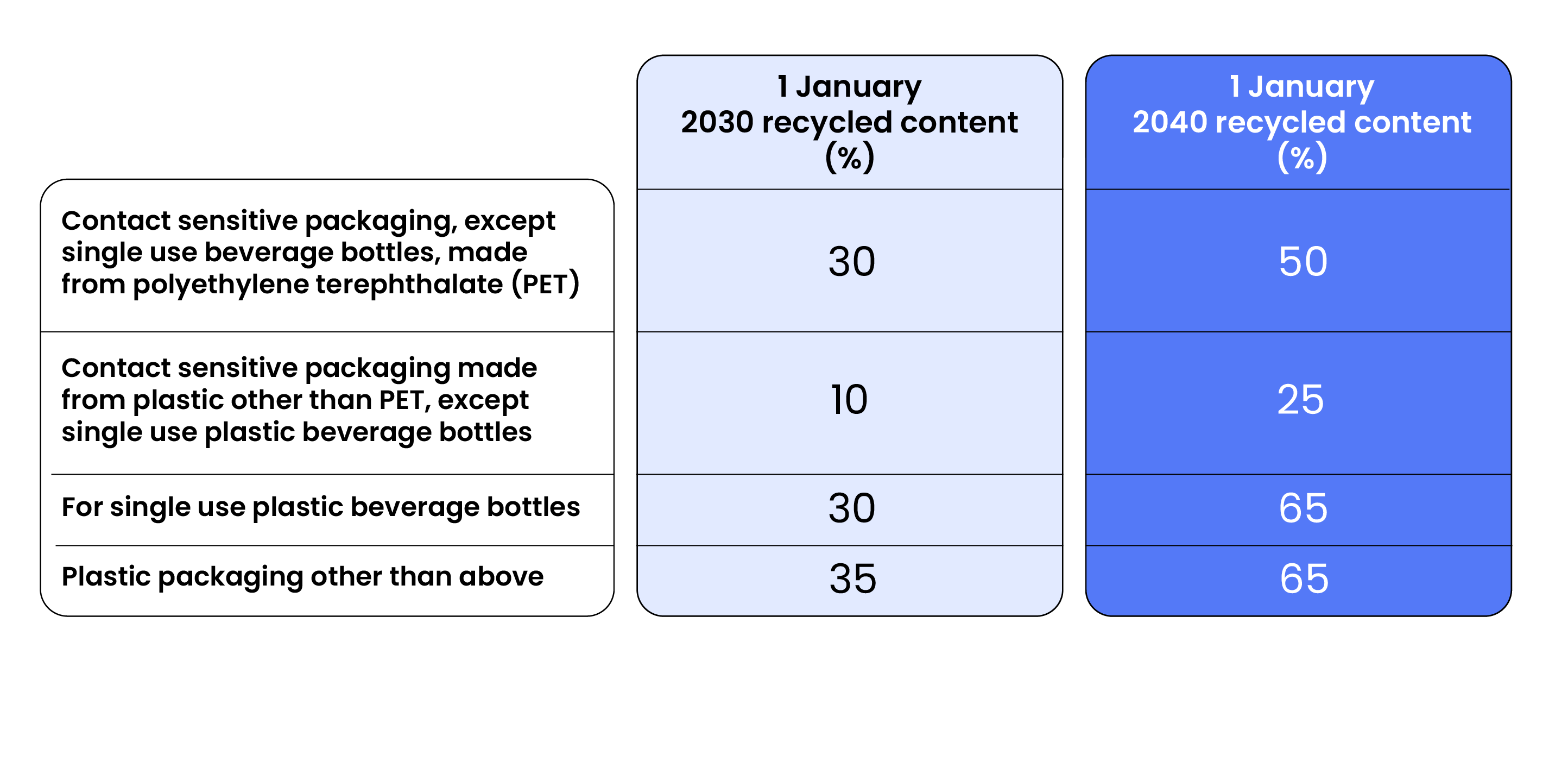

Minimum recycled content requirements for plastic packaging

The PPWR sets various minimum post-consumer recycled (PCR) content targets for plastic packaging for 2030 and 20401. By January 1, 2026, the European Commission will develop methods for evaluating, verifying, and certifying these practices, potentially involving third-party audits. As the recycling infrastructure improves, the capability to use PCR should also improve, making these goals more accessible than ever.

Other notable requirements of PPWR:

There is so much more to the PPWR, but some notable considerations and goals include:

- Increasing packaging reuse with specific targets for primary and transport packaging

- Minimizing Substances of Concern (SVHCs, PFAS, Heavy Metals)

- Supporting reuse/refill systems by 2029 at comparable costs to single-use products, mandatory for single-use plastic beverage bottles and metal containers

- Recommending QR2 codes® or other data carrier on packaging for consumer education on recyclability, composability, and material composition

- Minimizing packaging size to reduce weight and volume, including reducing empty space ratio to below 50%

Labeling requirements

Packaging must be labeled with harmonized material pictograms to easily inform consumers of material composition of packaging to facilitate sorting. A QR code or digital data carrier can be used to provide further sorting information, such as which component belongs in which collection bin.

Reused packaging in closed-loop systems must meet additional label requirements:

- A label indicating the package’s reusability

- A QR code or digital data carrier that provides:

- Information on the package’s reusability

- Tracking of the packaging

- Calculation of the package’s trips and rotations

Note: The inclusion of a QR code or similar feature is mandatory only in this context.

While not always mandatory, a QR code or digital carrier is recommended. With limited space on a product label, QR codes provide the user and supply chain a lot of information in a small format. Such suggested information includes:

- Informing users of material composition and destination for sorting

- Engaging consumers with recycling and reuse systems

- Explaining reusability and return/refill processes

- Sharing availability of reuse systems and collection points

- Signifying producer’s extended responsibility obligation compliance

- Educating on the PCR content, or bio-based material of the plastic package

- Communicating registered trade name, trademark, and contact information

Implications for packaging producers

PPWR is setting precedence for what the future holds for packaging regulations. The product packaging landscape will continue shifting toward more sustainable materials, and with the delegating acts to follow giving more specific guidance, the roadmap to circularity is set.

Packaging changes can’t be made overnight, so preparing for the recyclability requirements now is a must for brands that want to continue serving the EU market in the future. Actions to take:

- Assess your current packaging:

- Review what packaging materials you are currently using.

- Evaluate label space for inclusion of the packaging pictograms and any other information to share with downstream users.

- Think about the implications of a material change to your production line, consumer acceptance, and brand.

- Consider not just your primary packaging. E-commerce and transport packaging also have very specific requirements.

- Talk with your packaging material providers now to understand what steps they are taking to help their customers meet the recyclability, compostability, PCR, and reusability goals of PPWR.

- Consider your digital carrier requirements and design implications. Assess if you are required or prefer to add a QR code to your package. Evaluate the information you would want included and what level of variability the information will include.

- Prepare for EPR changes and fees. EPR isn’t new in the EU, but expect some changes and know what the expectation is from your organization

How advanced Videojet coding and marking solutions can help

The regulatory landscape for packaging is changing rapidly. This means that the packaging material choices are also changing and may require an alteration of your current marking and coding solution.

Videojet can help support in the transition to more sustainable packaging by offering a variety of marking and coding solutions that suit your unique needs. Whether the material contains recycled content, designed to be lighter or thinner, or even plant-based materials, Videojet will help you find the best solution.

Following the European Printing Inks Association (EuPIA) guidance, Videojet offers inks for continuous inkjet (CIJ) printers that will not impact the recyclability of the packaging. Additionally, laser technology creates permanent text and codes, including 2D codes, while minimizing consumable usage and meeting labeling standards.

Not sure where to start in adding 2D codes to your product? Start here and talk to Videojet today.

Sources:

https://www.eea.europa.eu/publications/plastics-the-circular-economy-and/ page 44

https://www.eea.europa.eu/en/topics/in-depth/plastics?activeTab=fa515f0c-9ab0-493c-b4cd-58a32dfaae0a

2 QR Code is a registered trademark of DENSO WAVE INCORPORATED.