When your ovens are on, your packaging printers need to be running too.

In the baked goods industry, Videojet can solve virtually any coding and marking challenge.

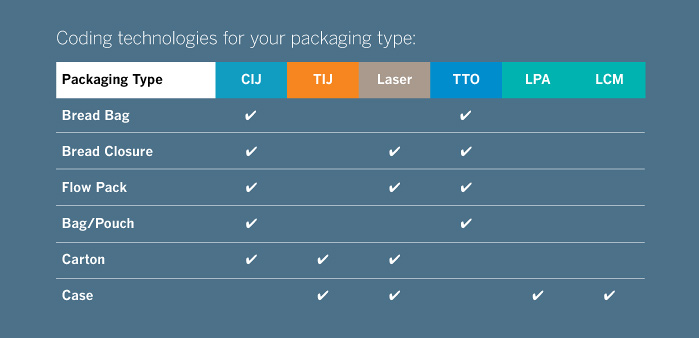

Whatever you’re baking – from bread and cookies to cakes and cereals – and wherever you need to accurately code information – from bread bags and pouches to cartons and cases – partnering with Videojet offers you key efficiency, operational and financial advantages.

- Applications

- Line Integrations

- Documents

- Overview

- Bread Bag

- Bread Closure

- Flow Pack

- Bag/Pouch

- Carton

- Case

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

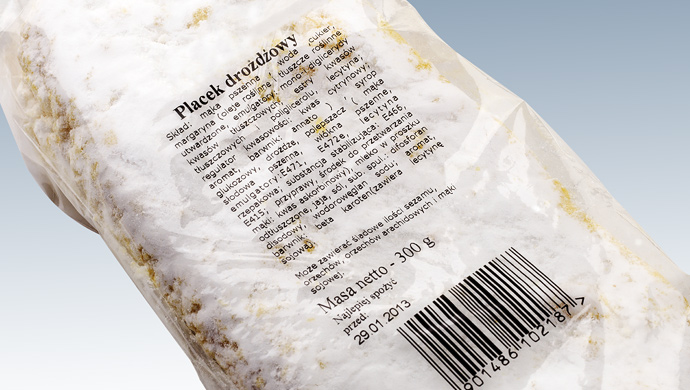

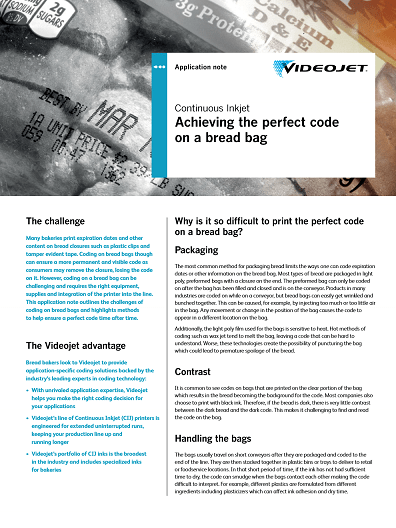

Getting a CIJ code on a bread bag can be difficult. Crinkling or too much air in the bag can ruin a code. Dark breads may also make a code on the bag difficult to read.

Simple solutions, such as adding a metal guide to flatten the bag, help deliver consistent and high quality coding while printing a code on a light colored pre-printed rectangle provides appropriate contrast with ink to avoid obscuring the code on a bag with dark bread as the background.

Continuous Ink Jet

(CIJ)

- versatile coding method for irregular or curved surfaces such as bread bags

- non-contact coding maintains product and packaging integirty

- variety of specialty inks including odorless and non-MEK inks

Thermal Transfer Overprinting (TTO)

- most commonly integrated with a label applicator

- can include both variable and static information such as bar codes, sell by date and price

- Code Assurance features help reduce coding errors

While bread in preformed bags is a common sight around the world, the type of closure used can vary from country to country and even within regions of a country. Twist ties, tamper evident tape and plastic clips are the most common closures. Additionally, the location of the code is variable. Depending on where you are in the world, bread may be coded on the bag, on the closure or both. Whatever your location and requirements, Videojet offers you a coding solution.

Continuous Ink Jet

(CIJ)

- suitable for most closures

- most effective when used to print a single line, such as a simple date code

- range of inks for different closure materials

Thermal Transfer Overprinting (TTO)

- simple, direct contact coding

- allows for more information to be printed on tamper evident tape than other coding technologies

Laser Marking Systems

- ideal for crisp, clear and permanent coding

- testing on your closure is critical before you purchase a laser for this application

Innovations in packaging equipment and industry trends are resulting in increasing flow wrapping speeds. You’ll want to take advantage of this growing capability for higher throughput and enjoy the effect it has on profitability. But cost-effective, high quality coding is still a necessity and not all printers are created equal. In fact, Videojet has matched these innovations in packaging speed with a range of coding options. Videojet can help you feel confident that your entire message will appear clearly and in the right space on the product, while still keeping your lines running.

Thermal Transfer Overprinting (TTO)

- produces high resolution codes on flexible film without solvents

- integrates directly into the line and prints on the film prior to packaging the product

- ideal for printing dates, logos, bar codes, nutrition facts, other product information and graphics

Continuous Ink Jet

(CIJ)

- meets the needs of high speed flow wrapping applications

- coding will be applied either before or after the product has been packaged

- code changes are simple through a user-friendly message creation interface or connection to networking software

Laser Marking Systems

- creates clear, consistent and permanent codes with limited consumables

- integrate directly with the flow wrapper to ensure more consistent placement of the code

- ideal for pre-printed polypropylene films as the laser can remove the ink without damaging the film

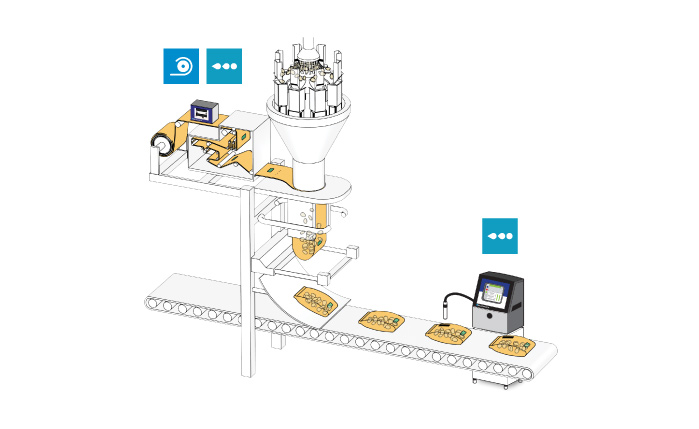

Managing multiple pre-printed films for multiple products running on the same line can be cumbersome and costly. TTO gives you the capability to print product information during packaging and variabilize mark content to limit pre-printed film variations. TTO can print high resolution logos, bar codes and product information, giving you the ultimate in flexibility and efficiency.

and standard code

Thermal Transfer Overprinting (TTO)

- directly integrates with vertical form fill seal machines (VFFS) to produce high quality codes

- work with an experienced partner as space to integrate on these machines can be limited

- suitable to print on lines with intermittent or continuous motion

Continuous Ink Jet

(CIJ)

- particularly useful for coding on more complicated applications such as preformed pouches and bags with very thick resealable zippers

- can seamlessly integrate with your VFFS equipment to take advantage of the material handling of the film

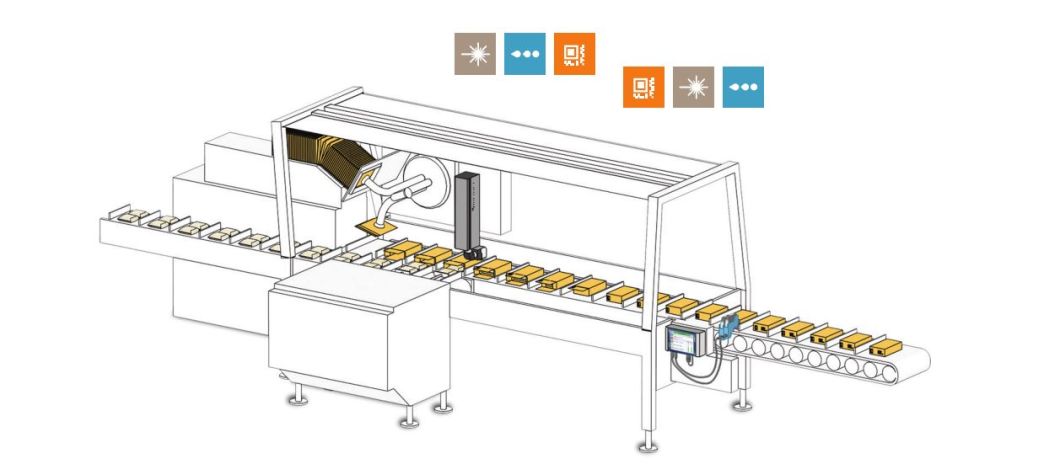

Coders are integrated either directly with a cartoner or on the outfeed conveyor after the carton has been filled and sealed. Although integration directly with the cartoner can require more planning, it offers you considerable benefits. These include more consistent coding due to more precise material handling and the use of existing guards on the machine. These advantages are similar for other types of packaging machinery.

Laser Marking Systems

- simple and clean method of marking text, bar codes or images while utilizing virtually no consumables

- a CO2 laser will remove a top layer of pre-printed ink to expose the layer underneath, resulting in a high quality, bright code against the dark background

Thermal Ink Jet (TIJ)

- high quality ink-based printing solutions that works best with either porous carton materials or in a print window that masks the aqueous overcoat

- prints at a higher resolution that other ink-based systems

- ideal for printing multiple lines of text, bar codes and other complex data

Continuous Ink Jet (CIJ)

- a versatile coding method

- codes adhere to virtually all common carton materials, including those with aqueous overcoats and other varnishes

- colored inks can be used to create contrast on different colored cartons

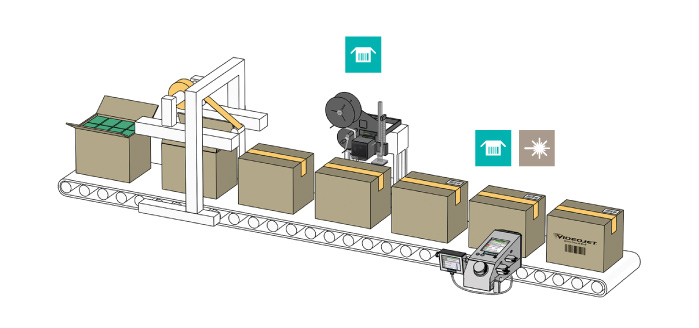

Printing lot, batch and supplier-specific information clearly on your cases creates a traceability point visible to your warehouse, wholesaler and retailer, thus providing rapid identification to aid effective movement of your products. Additionally, printing this information directly on the case simplifies packaging demands by standardizing to a common box style for different trading partners.

Large Character Marking (LCM)

- prints information directly on the case including scannable bar codes

- very cost-effective and dependable

- eliminates the cost, stocking and management of labels, as well as the need for customer-specific pre-printed cases

Label Print & Apply (LPA)

- high quality thermal transfer coding direct to the label

- delivers high resolution text and bar codes

- labels can be configured at the printer via an easy-to-use menu

- automatic application offers greater speed, accuracy and error prevention than hand labelling

Laser Marking Systems

- a DataLase® coated case marked with a laser will produce a dark black and extremely high resolution print

- print graphics, multisized text and bar codes directly onto corrugated boxes

- especially useful for water-resistant coated boxes, as it enables clear, dark printing without damage to the protective coating

- Bread Bagger

- Flow Wrapper

- Vertical FormFill Seal

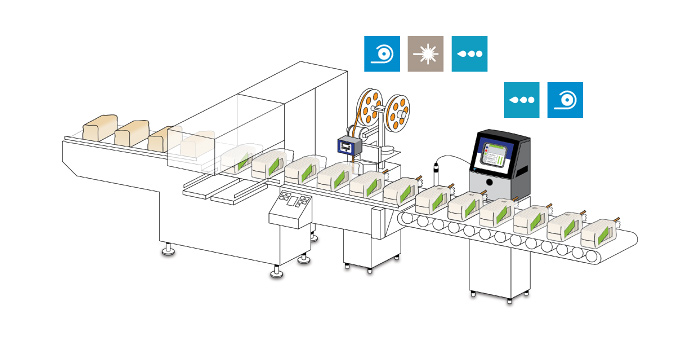

- Cartoner

- Case PackerAnd Sealer

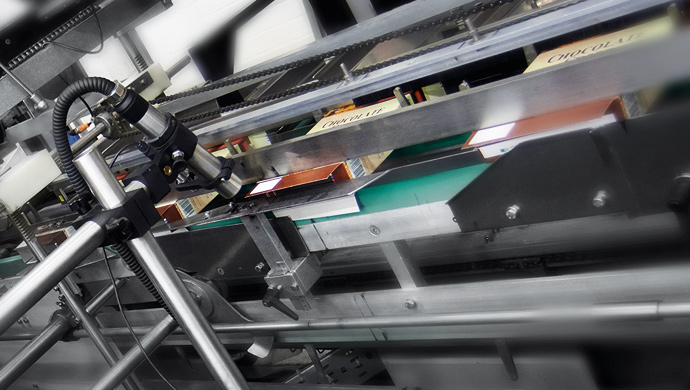

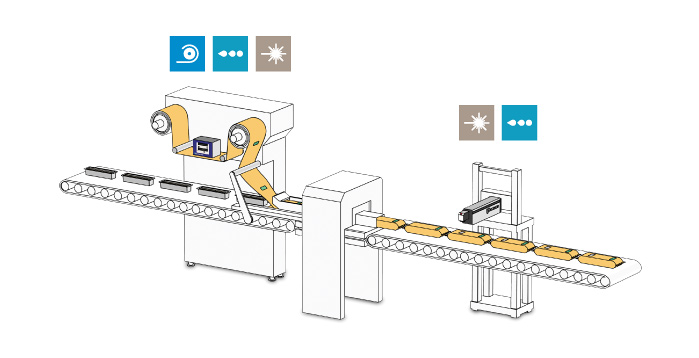

The use of preformed bread bags lends itself to a select group of coding technologies. The simple solution is to integrate on your conveyor to allow for bag marking after each product has been sealed and closed.

The type of closure you use determines whether it is possible to print on it and what technology should be chosen to perform the task. For optimal results, the printer should be integrated directly with the closure system.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Videojet has several solutions for flow wrapping applications regardless of your line speeds. Although coding downstream of the flow wrapper is possible, the highest quality codes are typically obtained by printing on the film prior to packaging.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Videojet has several solutions for flow wrapping applications regardless of your line speeds. Although coding downstream of the flow wrapper is possible, the highest quality codes are typically obtained by printing on the film prior to packaging.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Traditionally good material handling enables a range of technologies either integrated with the machine or immediately downstream in the outfeed. The optimal installation location will depend upon the size constraints of both the cartoner and the preferred coding technology.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Ink-based, non-contact printing using heat and surface tension to move link onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Printers are best integrated on your conveyor after the sealed case has been discharged. The type and amount of information you want to print on your cases determines which of our solutions is ideal for you.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Label Printer Applicator (LPA)

Print and places labels of various sizes on multiple package types.

- Brochures

- Application Notes

- Case Studies

- White Papers

Contact Us

Contact us Today for Free Consultation & Demo Samples:

South East Asia, Australia & New Zealand:

Mobile/ WhatsApp:+65 3138 2040

Videojet Thailand:

Mobile/Line:+66 92 272 0132

Videojet Vietnam:

Mobile/Zalo:+84 83 805 1033

Videojet Presence in SEA/ANZ Countries