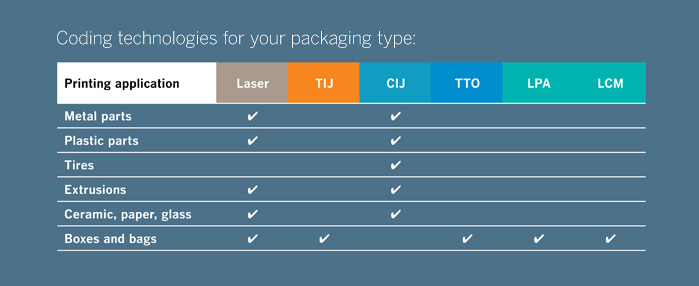

With so many parts and varying substrates, it’s important that your coding partner has the right mix of technologies to meet your part marking specifications.

Supported by a global team of technology specialists and our customer support team, Videojet has the expertise to help you design and integrate the right coding solution for your production lines.

- Applications

- Line Integrations

- Documents

- Overview

- Metal

- Plastic

- Tires

- Extrusions

- Ceramic,paper and glass

- Boxes and bags

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

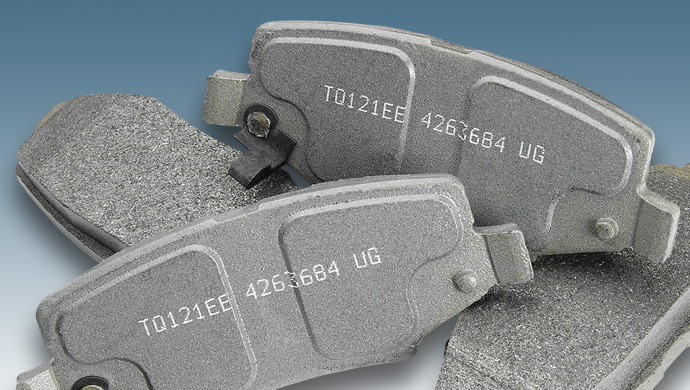

Print on titanium to aluminum and nearly everything in between.

Selection of an ideal coding solution for marking on metal parts will vary based on several factors. If permanent codes are required, for example, then laser marking is an optimal solution over continuous inkjet printing where ink performance can be less than ideal. With the intricacies of the strict specification of your parts, and the many available coding technologies, it is important that you select an experienced partner to guide you.

Laser Marking Systems

- Creates clear, high quality codes at up to 440 m/min

- Lasers code without inks or fluids, so consumables-related maintenance is not required

Continuous Ink Jet (CIJ)

- Smart Cartridge™ fluid delivery system means virtually no mess, no waste, and no mistake fluids replenishment

- Predictable maintenance windows and customer-replaceable components facilitate self-maintained environments

High contrast codes with maximum uptime

In an industry where most parts are dark or black in color, visual contrast is vitally important for both internal manufacturing controls as well as external traceability. High quality marks made with high contrast inks can help your codes achieve exceptional readability rates. And with proven installations across a wide array of substrates including polypropylene, polyurethanes, acrylonitrile butadiene styrene, and others, Videojet has the coding expertise to help you select the right solution for your substrate.

Laser Marking Systems

- Comprehensive portfolio of laser accessories, including lenses and beam turning units, to simplify line integration and maximize laser performance

- Videojet fume extraction systems help keep the production environment and marking lens clean

Continuous Ink Jet (CIJ)

- Ultra-high Speed (UHS) printers are ideal for high resolution codes, including DataMatrix, in small print areas

- Capable of printing DataMatrix codes with high contrast on dark surfaces

Print dots, characters, or logos in non-stop, hot environments

Coding on extruded rubber is done for purposes of internal tracking, high point indication, or for quality marking in meeting OEM compliance requirements. Producing codes on dark colored materials in hot and dusty, 24 hours a day, 7 days a week operations can be very challenging. As such, it is important to select printers that are tough enough for your environment, and that produce high quality, high contrast codes, even when printing upside down.

Virtually maintenance-free coding solutions for clear codes in challenging environments

Don’t let printers that require excessive maintenance be the cause of costly downtime. Even with extreme temperatures and wet and dusty conditions, we have Continuous inkjet (CIJ) solutions that can help keep your lines moving. Featuring anti-clog printheads, Videojet CIJ printers help address your unique production needs, including specialty inks that are fast-dry, heat, and oil-resistant. Likewise, our laser solutions are virtually maintenance-free and provide crisp, permanent, precision codes.

Continuous Ink Jet (CIJ)

- High contrast, specialty pigmented inks provide bright, crisp codes on dark backgrounds

- Dynamic Calibration™ automatically adjusts to variations in temperature or humidity, helping to keep your printers and lines running

Laser Marking Systems

- Sharp, clear codes with high contrast

- Highly attractive, gold-colored codes are possible on extruded PVC

Designed to print without damaging the integrity of your part

The unfortunate truth is that ceramic, paper and glass parts are susceptible to damage if they are not coded correctly. The selection and use of an inappropriate coding technology can result in the removal of protective layers, in the creation of holes or cracks in your part, or it can permanently change their physical characteristics. This is why it is imperative for manufacturers to select the right coding technology for their line or cell.

Continuous Ink Jet (CIJ)

- This technology supports the largest variety of material substrates

- Offers up to five lines of code per printhead, helping to increase print capabilities on your line

Laser Marking Systems

- Able to mark crisp, high quality codes without removing the protective external layer of your part

- Clean, high contrast appearance conveys a modern brand image

Reduce costs and increase packaging line flexibility

Printing information like product name and part number directly on generic boxes or bags helps reduce inventory holding costs. It also helps you avoid long lead times of preprinted materials as well as the time it takes to swap out packaging materials during production changeovers. Printing on demand can reduce packaging costs, simplify your production processes and increase productivity.

Laser Marking Systems

- Ablating on painted or labeled surface provides highly-legible codes

- Videojet 3000 Line marking systems are mobile and easily adjusted for varying package sizes

Thermal Ink Jet

- High resolution, ink-based printing with no wear parts, minimizing maintenance and related downtime

- Ideal for non-porous substrates, MEK-based inks help ensure good code adhesion

Thermal Transfer Overprinter

- Produces high resolution codes (300 dots per inch/12 dots per millimeter) on flexible film without solvents

- Patented, clutchless ribbon drive helps minimize maintenance-related downtime and maximize ribbon efficiency

Label Printer Applicator

- High quality thermal transfer coding direct to labels

- Automatic applicator offers greater speed, accuracy, and error prevention than hand labeling

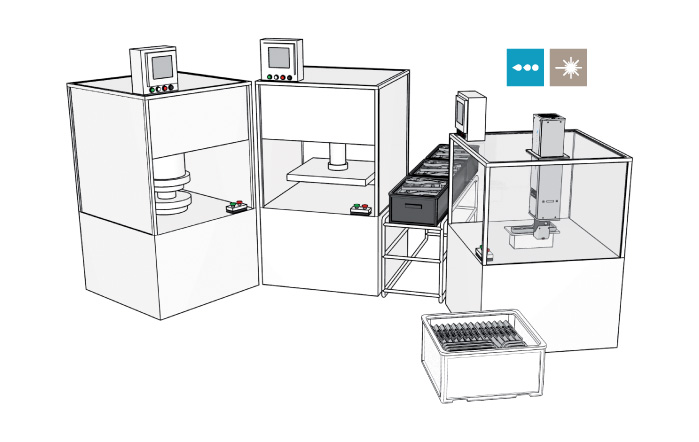

- Manufacturing cell

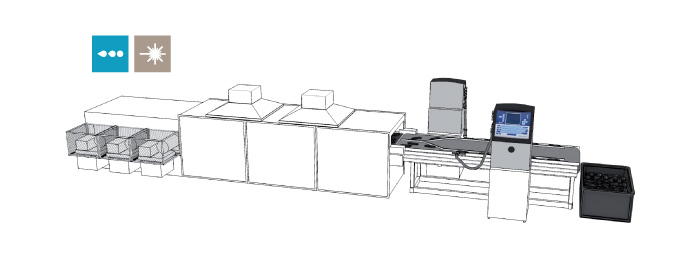

- Continuous line

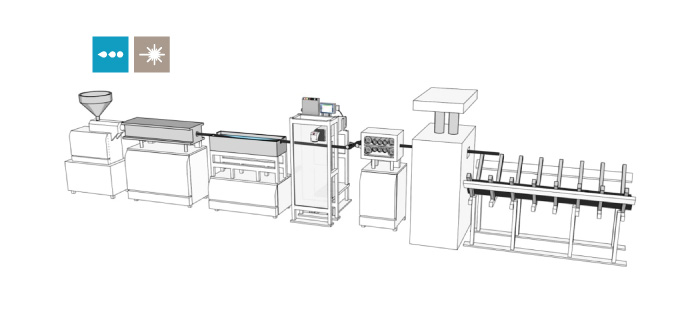

- Extrusion line

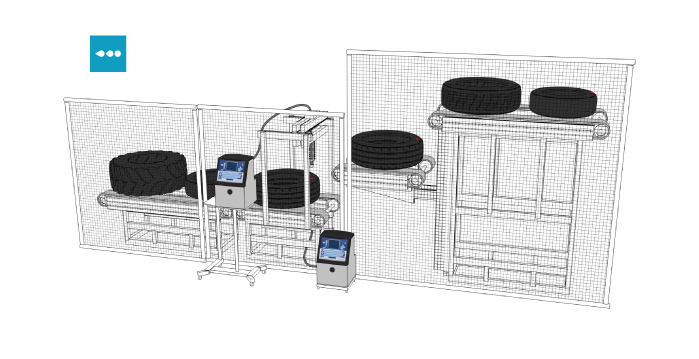

- Tire line

With direct connectivity to Programmable Logic Controllers (PLCs), small footprints, traversing arms, and a wide variety of beam turning units, Videojet lasers allow for easy integration into work cells.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Videojet printers can code at high speeds on many challenging substrates and do so without damage to the part. Coding options include simple lot code numbers as well as more complex DataMatrix codes.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Extrusion facilities are non-stop operations and are challenged by dusty and wet conditions. Videojet printers are designed to meet these unique demands and help deliver maximum uptime.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Tire facilities often run 24 hours a day, 7 days a week. Their coders print intermittently on dark materials in hot and dusty environments. Videojet printers offer high contrast codes with virtually ‘clog-free’ printheads.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

- Brochure

- Applications Notes

- White Paper

- Case Studies

- Infographic

Contact Us

Contact us Today for Free Consultation & Demo Samples:

South East Asia, Australia & New Zealand:

Mobile/ WhatsApp:+65 6718 0261

Videojet Thailand:

Mobile/Line:+66 92 272 0132

Videojet Vietnam:

Mobile/Zalo:+84 83 805 1033

Service Hotline for Singapore Customer:

Mobile:+65 6444 4810

Videojet Presence in SEA/ANZ Countries