In an era where sustainability is no longer a luxury but a necessity, the packaging industry is undergoing a significant transformation. Mono-materials are at the forefront of this change, offering a solution for those seeking to align environmental responsibility with the rigors of product lifecycle and packaging performance. Here is a brief look at how these innovative materials are contributing to the future of sustainable packaging.

Traditional flexible packaging solutions often involve a mix of different materials that are permanently laminated together to form the final substrate structure, complicating the recycling process and limiting the ability to recover valuable resources. Mono-materials, as their name suggests, are primarily constructed using a single substrate such as PE or PP. To provide shelf life and product longevity they may also have a very thin but high-performance barrier layer that doesn’t hinder recyclability of the packaging. These pioneering materials are not just a boon for the environment but are also engineered to match or exceed the performance of their traditional counterparts.

Performance Without Compromise

One of the most significant challenges in sustainable packaging is ensuring that the choice of packaging materials doesn’t mean sacrificing quality. Mono-materials are rising to this challenge, offering exceptional durability, flexibility, and other properties that are essential for protecting products. They are now helping to ensure that brands can provide the products as expected, and consumers are not forced to compromise on product safety or longevity when choosing more sustainable packaging.

Embracing Recycling Infrastructure

The true test of a sustainable packaging material lies in its ability to seamlessly fit within the existing collection and recycling infrastructure. Mono-materials are designed with this in mind, ensuring they can be easily collected and processed by recyclers, thereby converting what was once waste into valuable secondary materials. Recycling programs and infrastructure can vary by region but typically include collection sites convenient to consumers, such as grocery store drop off points and curbside collection.

Educating for Impact

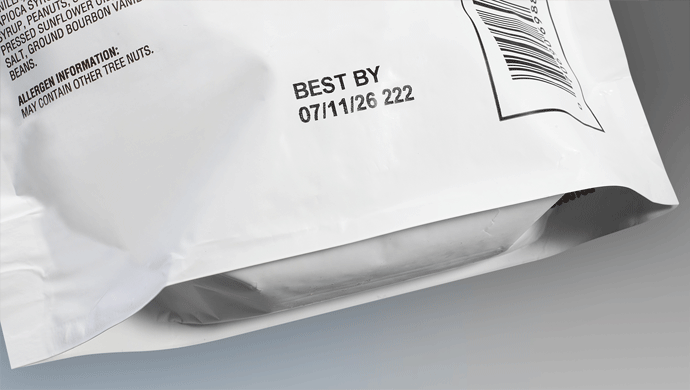

The transition to sustainable packaging also involves guiding consumers toward making more responsible choices. As mono-materials make their way onto shelves, parallel efforts are being made to educate the public on their recyclability, the importance of proper disposal, and the overarching benefits of supporting sustainable packaging. Mono-materials are typically printed with commonly known recycle symbols, whereas many legacy packaging films may have no recycle symbol or one with a strike through.

Sustainable packaging is only sustainable if both the package designers and consumers have the same goals and manage the lifecycle of the materials properly. If consumers don’t play their part, the positive impact of mono-materials simply can’t be achieved.

Designing for Circularity

A circular economy is the ultimate goal and mono-materials are a testament to the power of circular design. These materials are crafted to ensure ease of collection, sorting, and recycling, thus fostering a closed-loop system that minimizes waste and promotes the reuse of resources.

Stay ahead with real-time updates on the latest news:

Staying Ahead of Regulations

As governments worldwide create recycling and waste reduction targets, such as the European Union’s packaging and packaging waste regulation, producers have the obligation to find solutions that meet extended producer responsibility (EPR) regulations. Mono-materials offer companies a way to provide a recyclable, lightweight packaging to meet waste and recycling regulations and stay compliant. By adopting these sustainable materials, businesses can future-proof their packaging strategies and lead the charge toward a greener planet.

Customization Meets Sustainability

Innovations in mono-materials also mean that brands no longer have to choose between sustainability and customer experience. These materials can be tailored to provide the desired aesthetic appeal, tactile qualities, and functional attributes, helping to ensure that the journey towards sustainability does not detract from a brand’s identity or consumer satisfaction.

Mono-materials represent a significant leap forward in the packaging industry’s quest for sustainability. By marrying the needs of a product’s lifecycle with the performance of the product’s packaging, these materials are setting the stage for a future where sustainable packaging is the norm, not the exception.

Videojet offers a diverse portfolio of solutions that print clear codes, symbols, and product information and meet coding requirements on a multitude of packaging substrates, including mono-materials. From continuous and thermal inkjet printers, thermal transfer overprinters, and case coders, to laser marking systems, Videojet continually develops and tests solutions for excellent performance on the newest materials engineered for a circular economy.